| Wastewater collection system |

|

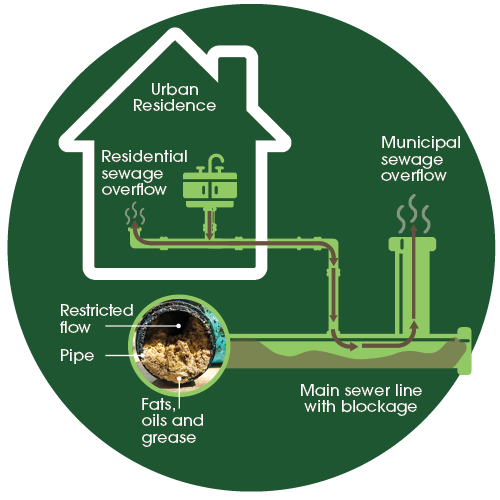

The wastewater collection system (WWCS) collects and transports wastewater sewage from all residential, industrial, commercial, as well as other facilities connected to the sewer system to the wastewater treatment plant. The collection system is composed of gravity sewers, force mains and pumping stations.

The municipal collection system is monitored continually and operated within compliance of all applicable legislation.

Wastewater collection staff are responsible for the maintenance of sanitary infrastructure, CCTV camera, cleaning, and pipe repair, catch basin and manhole restoration. Staff also participate in confined space entries and spill response.

|

| Septage Hauling Program |

| The Wastewater Treatment Plant operates a septage hauling program for residents that are not connected to the municipal sewage system. You will need a Septage Hauling Permit to access this service.

This service is only for depositing septage; no other waste will be accepted under this program.

|

|

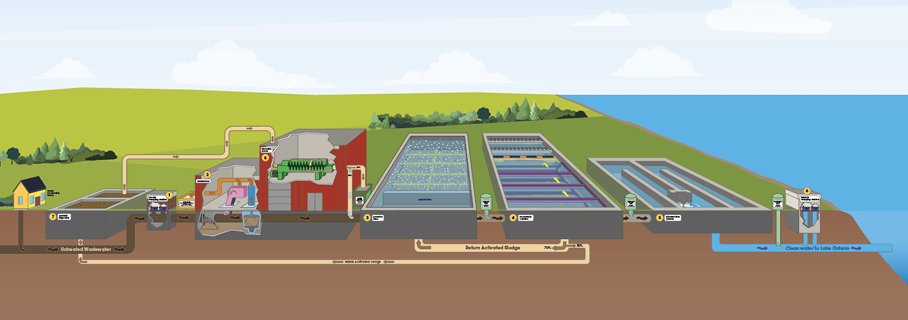

Once wastewater enters the Wastewater Treatment Plant, it moves through a series of structures, each with a specific function. Learn about this process step by step below, or download the PDF illustration. For further details, we also release a yearly wastewater performance report.

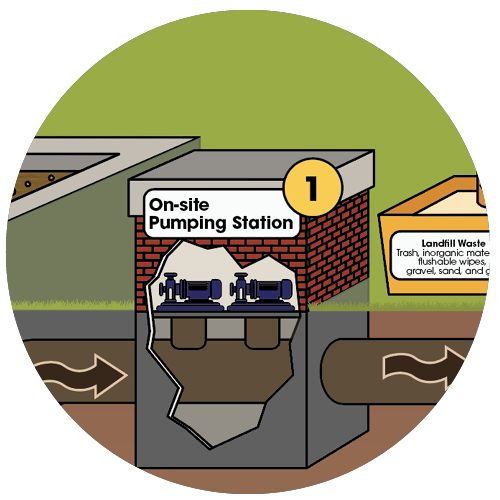

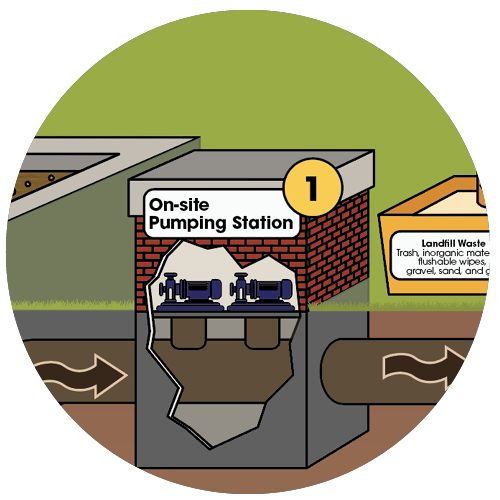

| Step 1: Pumping Station |

The pumping station’s purpose is to lift untreated wastewater (raw sewage) from a lower elevation, Wastewater Collection System, to a higher elevation, Wastewater Treatment Plant, so that the untreated wastewater can flow through the wastewater treatment process by gravity. |

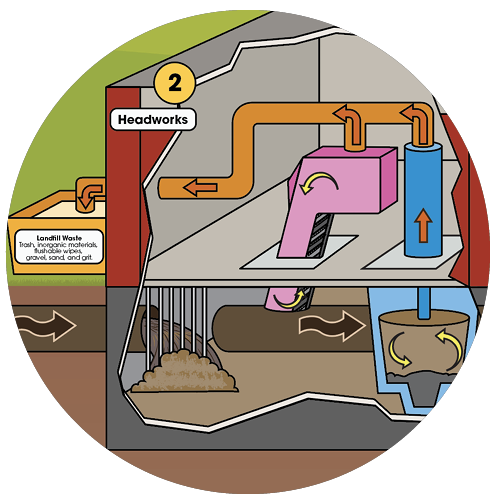

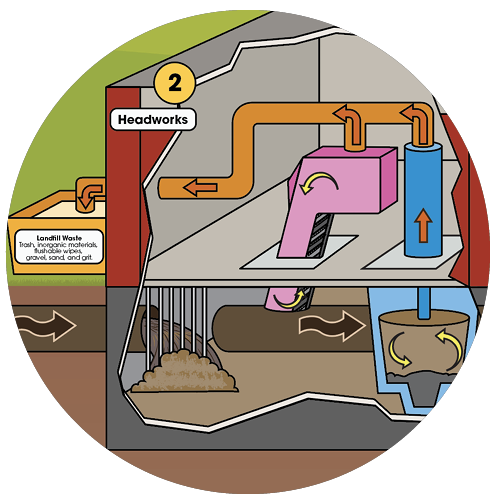

| Step 2: Headworks |

Wastewater entering Headworks facility frequently contains debris like trash, inorganic materials, flushable wipes, gravel, sand, and grit. To protect downstream equipment, the wastewater undergoes a series of mechanical screenings and grit removal processes to safeguard the downstream equipment. The mechanical bar screens (shown in pink) capture and remove large non-flushable items such as trash, inorganic materials and flushable wipes from the treatment process. The Grit Removal Vortex Tanks (shown in blue) use a circular motion to separate and capture the fine small non-flushable items such as gravel, sand, coffee grinds and eggshells from the treatment process. Collected screenings and grit are automatically washed, compacted, and sent to the landfill. Additionally, odorous air is captured and scrubbed during this process, reducing odours in the outdoor downstream process. |

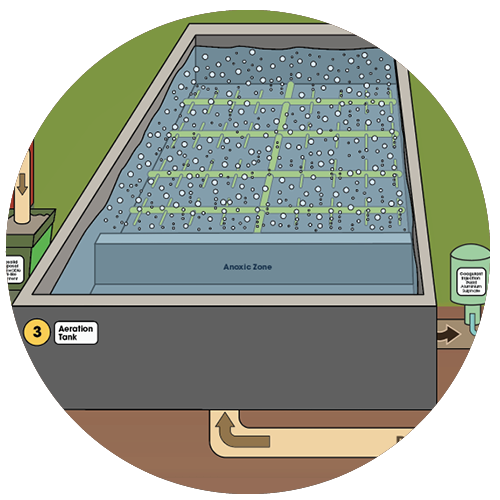

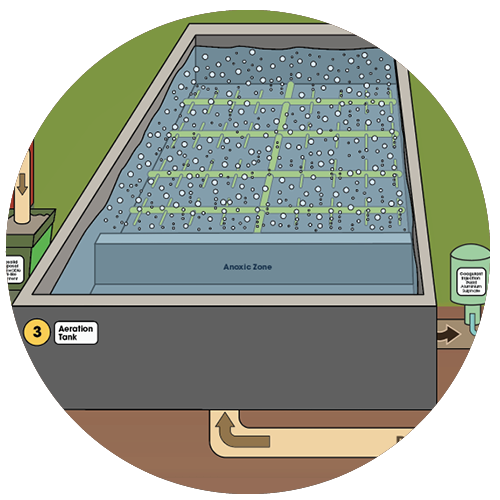

| Step 3: Aeration Tanks |

After preliminary treatment in Headworks, the wastewater is directed to the aeration tanks (Port Hope has 3 parallel tanks, only one is shown in this illustration). Organic matter, nitrogen, and ammonia are removed through biological treatment, and microorganisms consume the dissolved contaminants. The wastewater first passes through a small unaerated zone called the anoxic zone; where nitrogen and ammonia are biologically removed. The flow then continues to the aerated section of the tank, where energy-efficient fine bubble diffusers (shown in green) provide oxygen. As organic matter decays, it consumes oxygen, which is replenished through this aeration process. After exiting this tank, a chemical called Aluminium Sulphate is added to further thicken the wastewater before it moves on to the Secondary Clarifiers. |

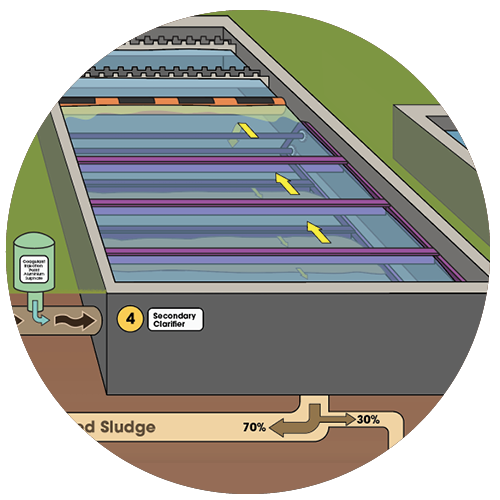

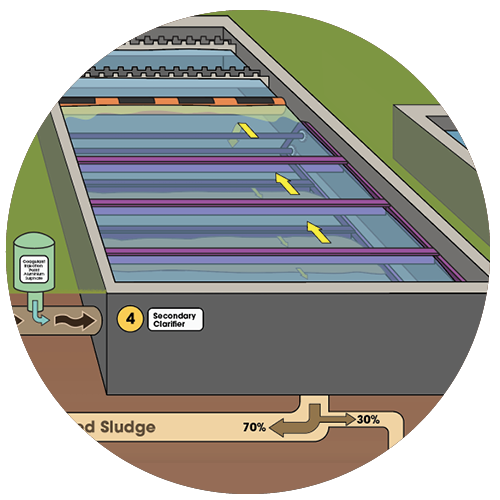

| Step 4: Secondary Clarifiers |

Following aeriation, wastewater is directed to Secondary Clarifiers (Port Hope has 3 parallel tanks, only one is shown in this illustration). This tank allows solids to settle to the bottom of the tank, while lighter materials can float to the surface. This tank features a "chain and flight" system that circulates water at a slow pace (illustrated in purple). The slow-moving rakes skim scum from the surface of the wastewater and directs it to a floating scum pipe for collection (illustrated in orange). Meanwhile, solids that settle at the bottom are scraped into a cross collector. Most of these settled solids, known as “return activated sludge” are redirected back to the aeration tank for additional treatment, while a smaller portion is sent to aerobic digesters for stabilization known as “waste activated sludge” (see step 7).

|

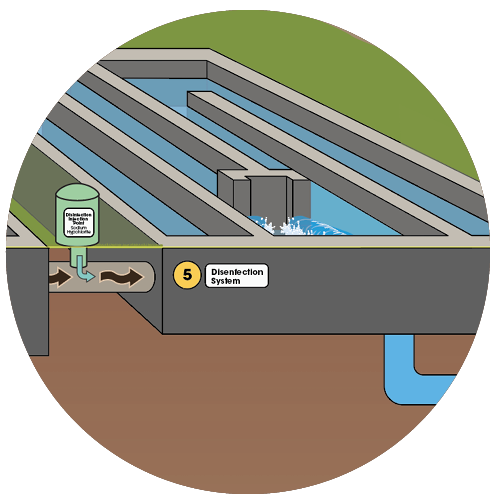

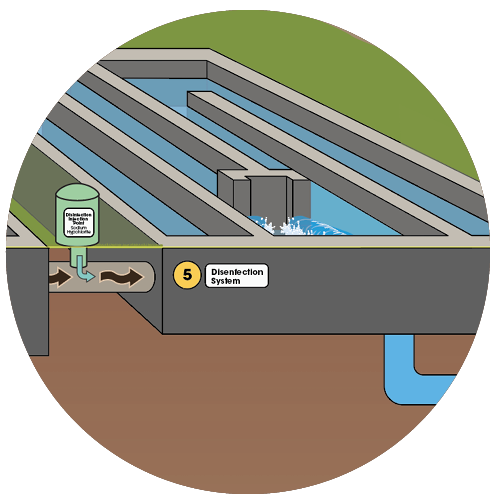

| Step 5: Disinfection System |

The disinfection system aims to lower E. coli levels in the final wastewater. Before the wastewater enters this tank, sodium hypochlorite is added to disinfect the water. Once the water exits the tank, sodium bisulphite is introduced to neutralize the chlorine, ensuring the water is safe for aquatic life. |

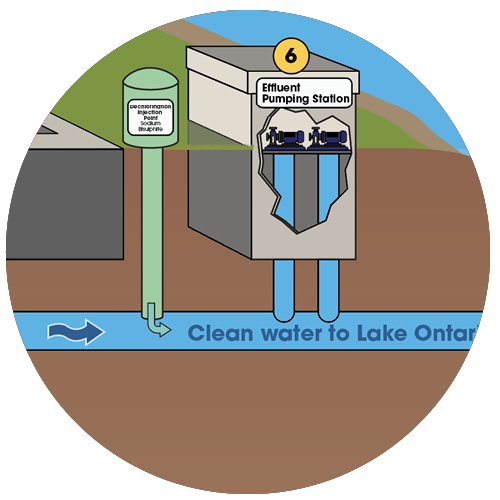

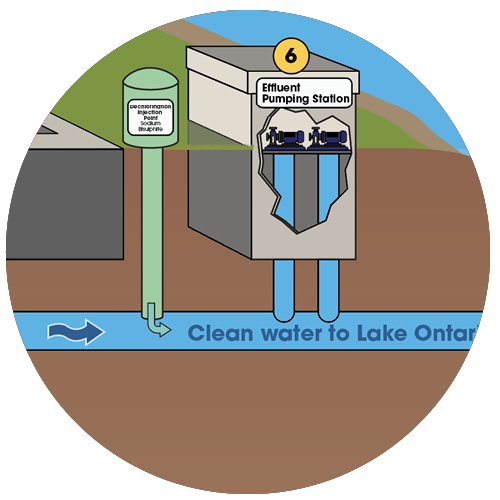

| Step 6: Effluent Pumping Station |

The treated water, now called “effluent”, is ready to exit the wastewater treatment plant. The effluent pumping station controls its departure by managing pressure, regulating flow, and preventing backflow. This is especially important when Lake Ontario's water levels are high, as it adds extra pressure on the outgoing water. These measures help prevent flooding at the treatment facility during peak flow or high lake levels. Under normal conditions, the water is typically discharged by gravity 236 meters offshore into Lake Ontario.

|

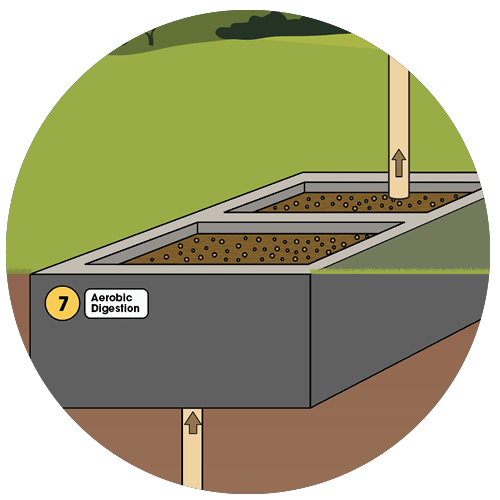

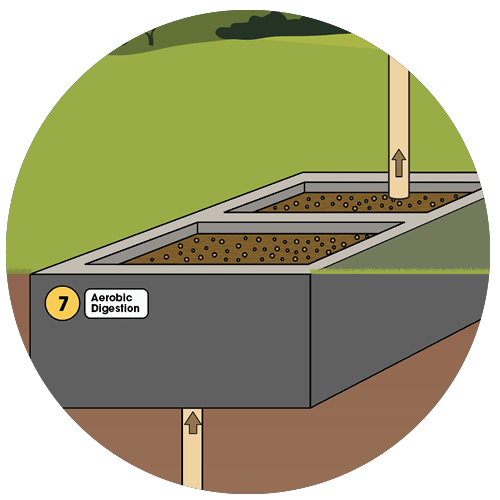

| Step 7: Aerobic Digesters |

Excess biosolids known as “waste activiated sludge” from the secondary clarifiers are sent to a two-stage aerobic digestion process for stabilization. In this process, the biosolids are first thickened in two separate aerobic digesters, where microorganisms break down the organic material in the presence of oxygen. This aerobic digestion reduces the volume of waste and stabilizes it. |

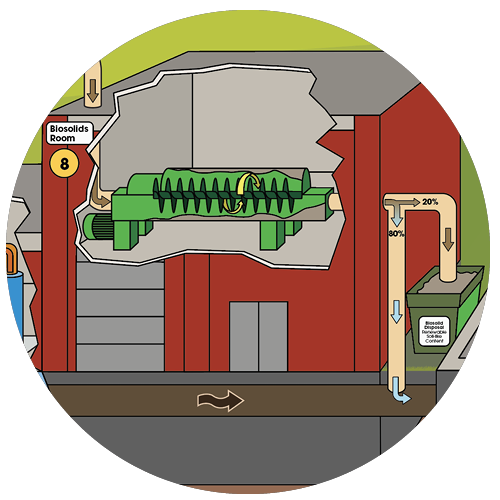

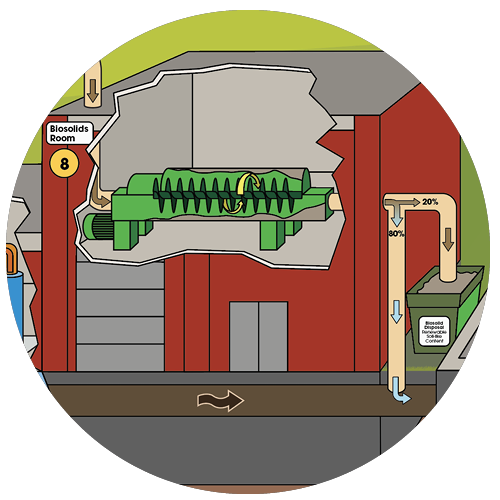

| Step 8: Biosolids Room |

The thickened biosolids are then moved to the biosolids room, where a dewatering centrifuge (indicated in green) further reduces the volume of waste. This process condenses the biosolids to just 20% of their original volume, producing a moist, soil-like material that complies with all Ministry of Environment guidelines for beneficial reuse. The remaining 80% of the wastewater is redirected back through the treatment process. |

|

From sink to sewers

From sink to sewers